SERVICES

ENVIROMENT PROTECTION

DESCRIPTION OF THE TECHNOLOGY OF OIL SLUDGE TREATMENT

1. GENERAL CHARACTERISTICS OF OIL SLUDGE

In the simplest form the oil sludge consists by physical-chemical systems and multi component stable aggregates, consisting mainly of oil, water and mineral additives (sand, metal oxides, etc.).

Due to the substantial dispersion of the composition oil sludge variation of the differential physico-chemical characteristics is also very broad. The oil sludge density fluctuates in the limits from 830 to 1700 kg / m³, the freezing point is from-3 °С to +80 °С. The combustion temperature is in the diapason from 35 to 120 °С.

Across the range of characteristics of different oil waste in all its general type, all the sludge can be classified into three groups in correspondence with the conditions of their formation: soil sludge, bottom sludge and tank sludge.

Soil sludge formed as a result of oil spills down derivatives in the process of industrial operations, or in case of failures.

Bottom sludge appears to settle spills of petroleum products at the bottom of reservoirs and water areas, and tank sludge are formed during storage and transportation of petroleum derivatives in tanks of different designs.

1.1. soil sludge.

With the breaking of oil pipelines, if it is possible, all the topsoil is evacuated to warehouses where treatments are added biopreparations, lands are added and allowed to naturally decay.

The main cause (excluding financing) of oil sludge problem-is the lack of specialized companies, able to settle for a quick and effective spill able to complete absence of an infrastructure.

The second cause is the absence of the corresponding special equipment.

1.2. bottom sludge.

The situation with the bottom sludge around the world today is characterized as catastrophic, since no one knows what to do with the layers of a meter and more of oil derivatives in the bottom of the loading ports and transshipment of oil products.

The causes of the problems are the same as in 1.1

1.3. TANK SLUDGE.

Tank sludge formed during cleaning technology of tanking parks by the equipment owner. During the cleaning technology all oil sludge must undergo recycling, i.e., to be sent to special polygons.

The fundamental cause of the formation of tank sludge is the physicochemical interaction of petroleum products in the receiving space volume of petroleum products with moisture, oxygen content in the air, and the mechanical impurities, and also with the material of the tank walls. As a result of these processes occurs the partial oxidation of initial oil products with the formation of resin-like unions and oxidation of the walls of the tanks. Also the moisture input to the volume of product oil and mechanical impurities lead to the formation of emulsions of aqueous and oily dispersions minerals. Whereas, any oil sludge is formed as a result of interaction with the surrounding concrete with their own condition and during a period of time, then similar sludges in composition and physical-chemical characteristics do not exist in the nature.

According with the results of many investigations in the tank sludge the correlation oil derivatives, water and mechanical impurities (particles of sand, clay, rust, etc…) fluctuates in very broad differential: hydrocarbons are in the order of 5-90 %, water in 1-52%, solid impurities in 0.8-65%.

The companies that own the tank farm (oil companies, refineries) create pits of open type, evaporator lakes, etc. for storing the waste oil.

During long-term storage tank sludges in the course of time are divided into several layers with characteristics by themselves for each.

The upper layer is represented by an aqueous oil product containing up to 5% of mechanical impurities and fine dispersion of emulsion type corresponds to the “water in oil”. In the composition of this layer falls to 70-80% of the oils, asphaltenes 6-25%, 7-20% resins, 1-4% paraffin. The water content does not exceed 5-8%. Very often the organic part of the fresh layer of oil sludge in its composition is very similar to the initial petroleum product stored in the tank. This situation is very common in the storage tanks of gas stations.

The middle layer is comparatively large in volume is represented by an emulsion of “oil on water”. This layer contains 70-80% of water and 1.5-15% of the mechanical impurities.

The next layer is composed entirely of stagnant mineralized water with a density of 1.01 to 1.19 g/cm ³. And finally, the bottom layer (bottom sludge) is normally represented by a solid phase, which includes up to 45% of organic material, 52-88% of the solid impurities, including iron oxides. Because the bottom sludge mass is hydrated, the water content in it can reach 25%.

Sludge oil tank are the most technological of the total volume of oil sludge can be “lifted” and repaid to the technology of oil production.

However, oil sludge still not a source of raw material for further processing, but a major ecological problem.

The causes of the problem are the same as in 1.1.

Moreover, it also affects those responsible for oil waste not want to have financial and other risks associated with the extraction type, and others, and the processing of technogenic deposits.

2. SOLUTION OF THE PROBLEM OF OIL SLUDGE PROCESSING.

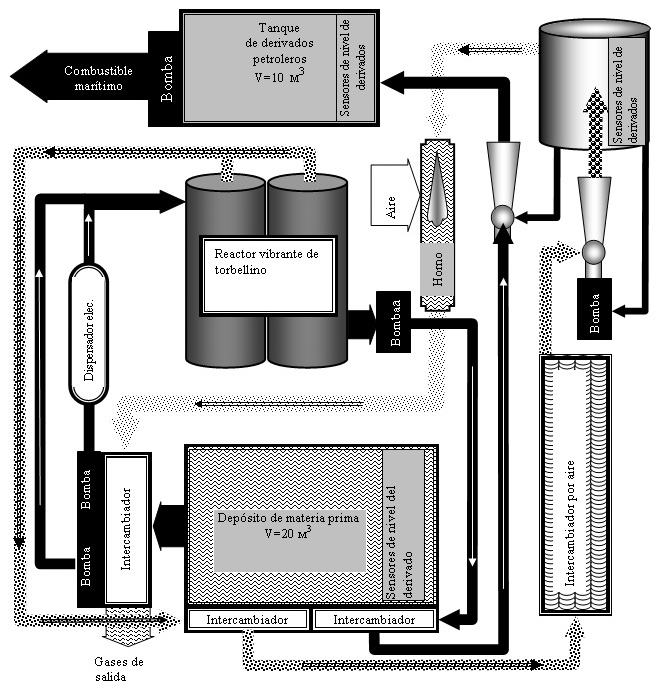

We have designed, manufactured and certified V&V RENDING S.A. and partners the stationary and mobile complexes for lifting, cleaning from mechanical impurities, disposal and treatment of water and salt removal from bottom (pit) sludge of fresh and of prolonged storage, to obtain from them marketable goods, and for further processing and to bitumen for construction and marine fuel with consequent soil regeneration.

Here we will discuss about the complex mobile oil sludge processing, because the stationary complex designed based on our technology are worthy of a separate topic.

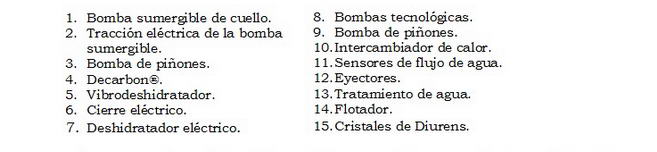

These mobile complexes allow all complex technological operations with a small energy expenditure and storage in remote areas of the sludge away from industrial areas and urban areas, which therefore does not have a production infrastructure.

The mobility of the complex enables the entire cycle of operations directly “on wheels” without building temporary structures and other types.

These complexes do not have analogs in the world.

The patent protection requirements have been implemented by the patent of Russian Federation № 2203482 of 01.11.2001.

Comparison Table of the complex with an analog stationary (refinery).

№ Indicator Refinery Complex

1. Autonomy (diesel generator) – Yes

2. Mobility (Transportable) – Yes

3. Expulsions to atmosphere Yes No

4. Energy consumption per m³, kWt 50-100 5-11

2.1. INSTALLATION OF OIL SLUDGE CLEANING.

THE INSTALLATION OF OIL SLUDGE CLEANING is a facility for the lifting, removal of water, salts and from bottom (pit) sludges and for further processing in refineries or in THE INSTALLATION OF OIL SLUDGE PROCESSING.

The installation is carried out constructively in a single module, which reduces commissioning time before the commencement of works and for transportation position after termination of these. The great advantage of the system is its mobility. The high degree of cleanliness allows sending processed sludge to a refinery for further processing.

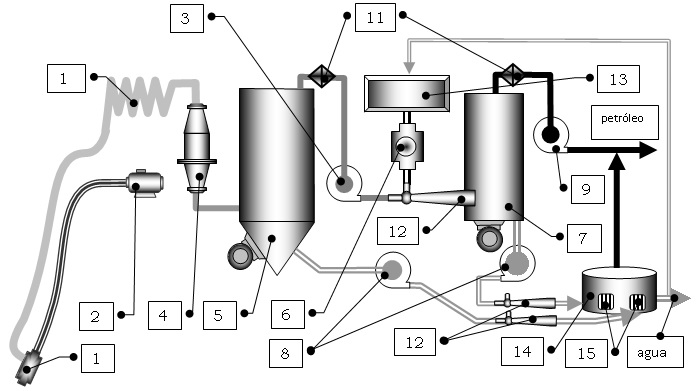

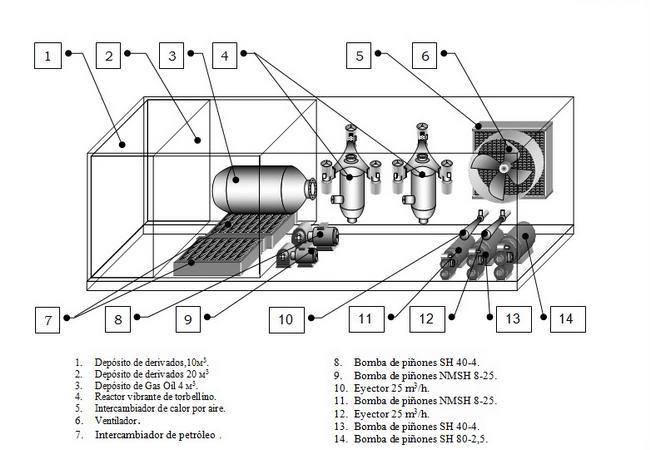

THE CLEANING INSTALLATION OIL SLUDGE consists of a container (20 ‘) divided into two compartments by internal partition walls and consists of:

· Tank for sludge processing;

· Engine compartment

In the engine compartment are the following equipments:

· Vacuum vibrating Dehydrator;

· Electric Dehydrator;

· Block float;

· Magnetic Inductor Decarbon®;

· Cationic block of water treatment;

· Ejector Pumps

· Vacuum Pumps;

· Diesel generator;

· Set of engineering tools of the installation.